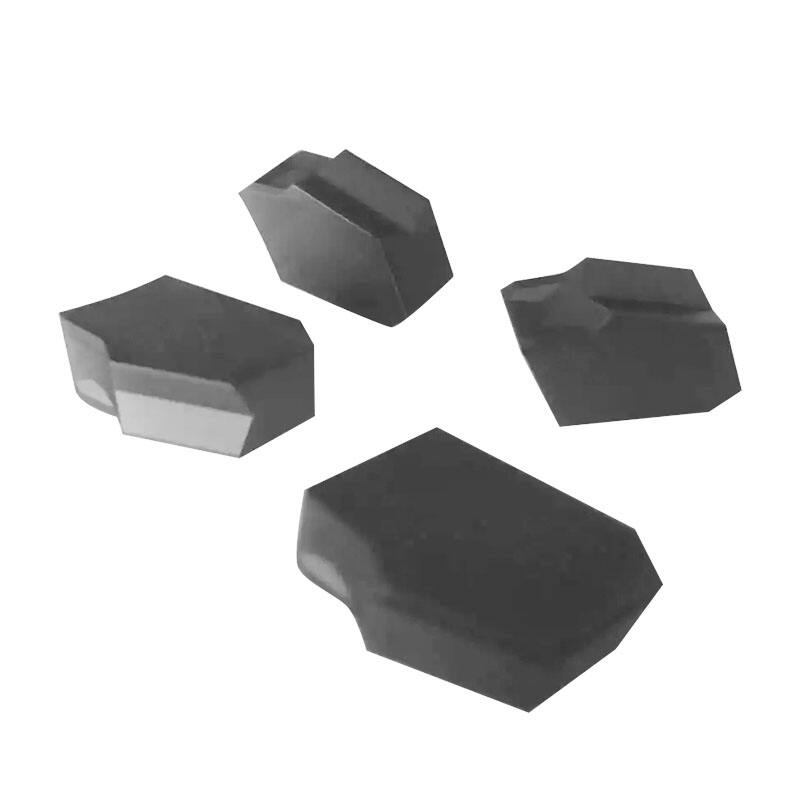

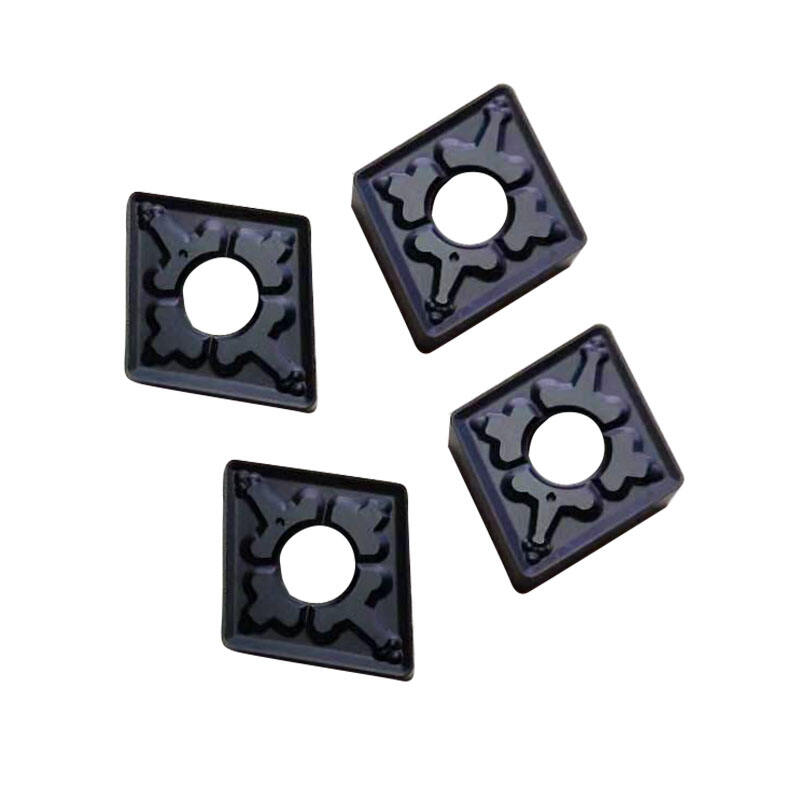

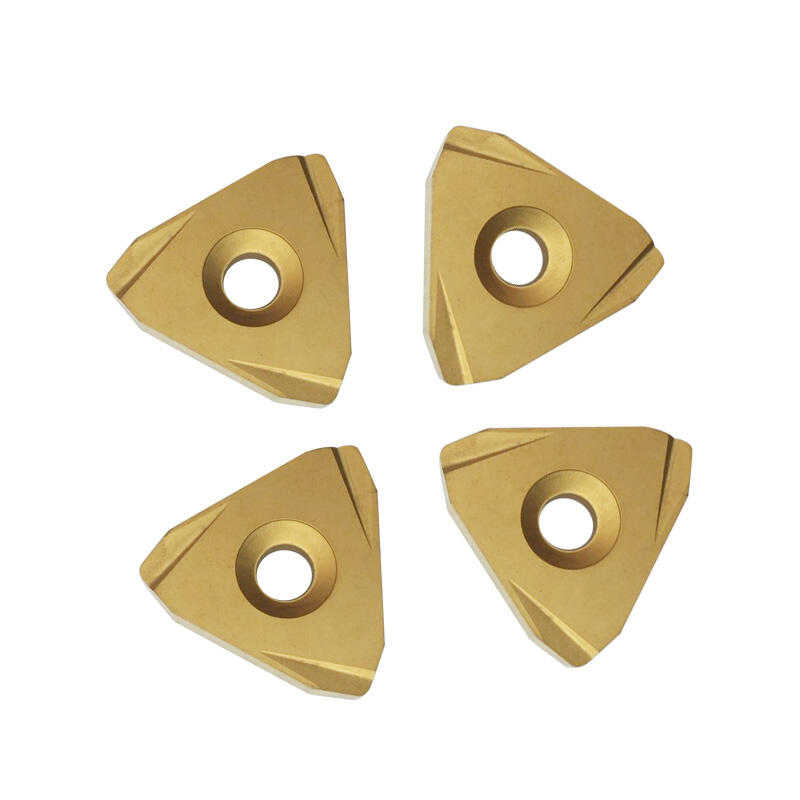

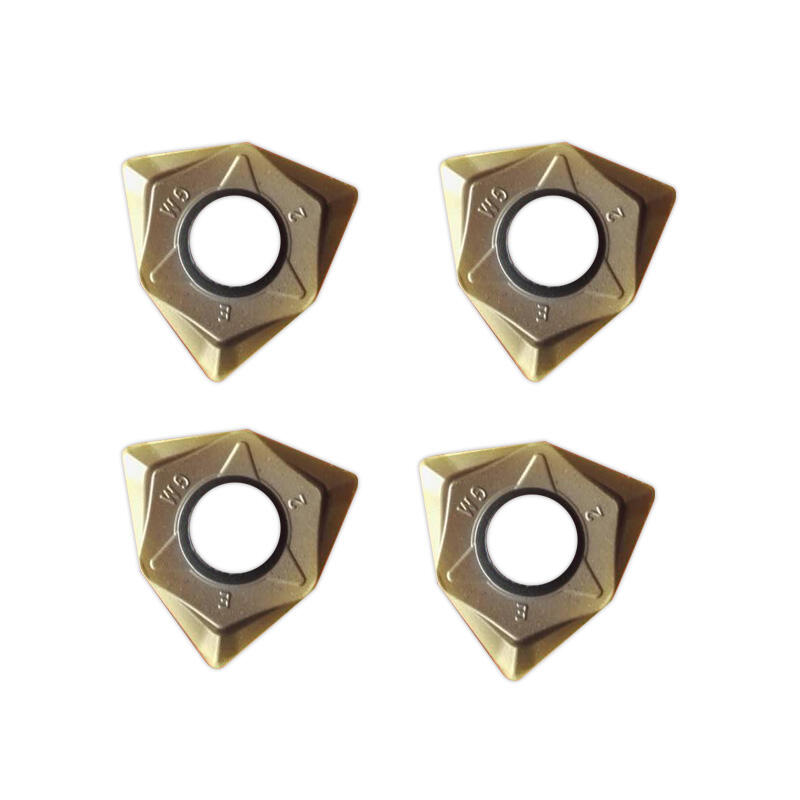

Uses of Tungsten Carbide Inserts

Thousands of business owners and construction workers worldwide use tungsten carbide inserts to enhance their productivity.

Do you know why tungsten carbide inserts are so great? Then, read about the advantages listed below.

• Carbide inserts are more efficient and cost-effective than similar tools.

• A tungsten carbide tool lasts much longer than a carbon tool and is highly durable.

• The tungsten carbide material is available in over a dozen different grades, all of which apply to other applications.

• As cutting tools, tungsten carbide produces a much better surface finish.

• The abrasion resistance of carbide tools is exceptional.

• Their resistance to catering and thermal deformation is high.

• Tools made of carbide have high wear resistance, allowing the user to use them at higher speeds and more extended periods than tools made of other materials.

• The cost of diamond tools is lower than that of steel tools.

• Tools made from carbide are capable of machining hardened steel.

• Tools made of carbide are chemically inert.

Further, carbide recycling materials like tungsten carbide inserts have many uses that are essential to many businesses. So let’s take a closer look.

Get more information about tungsten carbide and Lathe Machine Cutting Tools by contacting estoolcarbide.com.

Grooving Inserts, Turning Insert, Threading Inserts, Milling Insert, Indexable Carbide Inserts, Cutting Tool, Drilling Insert

wnmu080608 | turning inserts factory | Grooving Inserts | Threading Inserts | Milling Insert | Lathe Machine Cutting Tools | Cutting Tool | Indexable Carbide Inserts | bide insert | china milling inserts | tungsten carbide inserts ztfd0303-mg |

Other links:

bookmarkstar | 4mark | expatriates | getdailypost | estoolcarbide | wikipedia